BETHLEHEM, Pa. — In his 28 years in the beer industry, Jeff Fegley has learned to roll with the punches.

“I’ve seen many materials change in price and obviously, everything has gotten consistently more expensive over those years. Really nothing has gotten cheaper,” said Fegley, who operates both the Bethlehem and Allentown Brew Works locations.

That’s familiar territory for many businesses, and for owners working to control costs while running on already narrow profit margins.

But as President Donald Trump again plans to impose tariffs on imported steel and aluminum, local brewers say there could be a significant impact on their bottom line, as they rely heavily on those metals for production and packaging.

“I do believe that an increase in the cost of the cans, and ultimately the cost of the product to the consumer is going to hurt our industry even more."Jeff Fegley, owner of Fegley's Brew Works in Allentown and Bethlehem

“I do believe that an increase in the cost of the cans, and ultimately the cost of the product to the consumer is going to hurt our industry even more,” Fegley said, with any increase in the cost of materials potentially passed on to the consumer.

“Our industry is already struggling post 2020, with several factors. I mean, the craft consumer has changed, and the marketplace has been super saturated with craft beer and distillery licenses, specifically in Pennsylvania,” he said.

“So the impact of the aluminum is also going to face other competing products, such as RTDs (ready-to-drink beverages). That would be your malt brewed beverages that aren't beer.

“So it's going to impact everyone in many aspects the same way. It ultimately hurts the consumer, and it hurts the businesses, because the consumer will purchase less products that have a price increase due to inflated materials, such as aluminum.”

25% tariffs

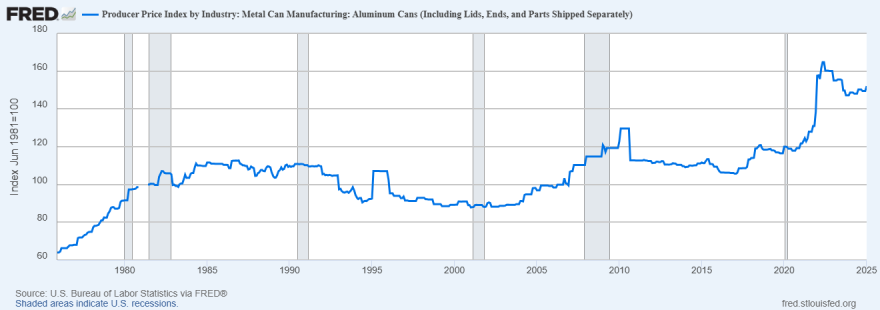

Barring any reprieve, Trump’s plan for a 25% tariff on imported steel and aluminum begins March 12, reviving a similar move made in 2018 during his first term that, even with exclusions, caused production pains for breweries due to price increases on raw aluminum.

Now, with no exclusions planned for countries like Canada — where the U.S. gets the bulk of its aluminum — brewers say it will undoubtedly increase prices on aluminum products.

The Brewers Association, a trade group representing more than 5,000 American breweries, said current data indicates approximately 75% of packaged craft beer is sold in aluminum cans.

That makes it hard for local brewers to explore options to mitigate the impact of the tariffs, such as finding alternative suppliers.

“The highest packaging cost is the can. That will cost you $10 a case, or more, depending on where you’re getting it from,” said Beau Baden, owner of Sherman Street Beer Company in Allentown.

And then, he said, there’s a ripple effect elsewhere, including tariffs ultimately driving up the cost of materials used to brew and house beer as the industry contracts, with more craft breweries closing than opening nationwide in 2024.

As businesses close, equipment has flooded the market.

“There’s so much stuff for pennies on the dollar compared to what new equipment is (costing). But it’s going to inflate the price of the used market, because they’re not going to take that. They’re going to go, ‘Well, you’re now paying 25% more for new, so we’re going to charge 25% more for used.”

All of it will have a direct impact on manufacturing companies that make a variety of steel products, including tanks, kegs and more.

“We’re insulated from some of that,” Baden said, with Sherman Street a small, 3-year-old brewery not focused on buying additional equipment or planning any expansions at this point.

“But it's definitely going to effect stuff down the line,” he said.

'Be prepared'

It’s difficult for Fegley, Baden and others to think about a potentially higher cost environment going forward and if there’s anything they can do to prepare.

“I think what I’ve learned over the time is not to panic and not make rash decisions,” Fegley said, putting the looming tariffs up against a similar problem that occurred during the 2007-08 hops shortage.

“With the growth of the breweries popping up, plus there were some hop supply issues with weather, hops skyrocketed. And then everyone in the brewing industry started contracting hops for the future,” Fegley said.

“In the end, that was ultimately a terrible decision from breweries, including myself, because we got stuck with very expensive prices on hops and a supply level that most most breweries were not able to meet because the market shifted to more and more and more breweries popping up.

“So sales declined as a percentage, as a category, overall, beer went up, but those producing beer during the boom, or before the boom, saw a decline in those sales. It was a double whammy.

“This time around, you know, with the aluminum, it's ‘be prepared,’ but it's certainly not going to be ‘let's purchase aluminum futures.’ And, you know, make sure that we have our supply in the future, because the market will correct itself.”

Fegley is optimistic that everything happening is typical with a new administration. He believes there will be fluctuation, and ultimately the tariffs will be lifted.

“It’d be a matter of time. And how long will that be? I have no idea, but we've seen from this administration that sometimes it's pretty quick changes," he said.

“So, the mentality for our business is going to be wait and see. Be prepared to wait and see, because anything rash could be worse than just waiting.”

Baden, meanwhile, says finding alternative can suppliers, stockpiling cans to beat the tariff increase, and adjusting pricing and production strategies would be difficult.

“If 10 trucks are coming and you get 10 trucks (full of cans), now it affects cash flow," he said. "You’ve got to be able to weather having all those on the floor for several months before you see that money coming back in. So that affects the bottom line as well.

“You know that cash flow is king in this business. If you don't have that cash flow, you can't sustain the ups and downs of what this business is.”

"Cash flow is king in this business. If you don't have that cash flow, you can't sustain the ups and downs of what this business is."Beau Baden

Brewed in steel, canned in aluminum

Across the country, fewer and fewer breweries use bottles in their production line, especially with more diversified options such as canned cocktails, hard seltzers and non-alcoholic options.

But the reality is that moving from cans to bottles isn’t possible for most small breweries, as packaging equipment is completely different.

Ron Beitler, a Lehigh County commissioner and the owner of Rising River Brewing in Macungie, said his business does a limited amount of canning, and the impact of tariffs would be less severe than on fellow Lehigh Valley Brewers Guild members who focus heavily on distribution.

“We already operate on razor-thin margins due to the cost of goods and government-imposed expenses — including taxes, fees, compliance requirements and regulatory mandates,” Beitler said.

“We hope federal policymakers consider the impact — especially on small businesses like ours, which face the greatest challenges absorbing costs tied to government policies.”Ron Beitler, owner of Rising River Brewing

He said Rising River would strive not to pass costs onto customers, but the impending tariffs may make that difficult for certain products.

“We'll do everything we can to avoid it, possibly by shifting focus to reusable glass growlers,” Beitler said, noting growlers in the taproom are filled off the taps.

“Bottling with glass for mass production — getting your product on shelves outside your taproom — involves very expensive equipment. It’s an important distinction when we say we can push growlers in-house.

“Big picture, we’re willing to do our part short-term to support a stronger U.S. manufacturing environment," he said.

“We hope federal policymakers consider the impact — especially on small businesses like ours, which face the greatest challenges absorbing costs tied to government policies.”